Indicators on Glazing Infill Panels You Should Know

Table of ContentsThe Definitive Guide to Infill PanelSome Known Factual Statements About Mapes Insulated Panels How Glass Infill Panels can Save You Time, Stress, and Money.

The outdoors face of glass, outside glazing products and the outer subjected face of light weight aluminum framing function as a rainfall display, losing water away. Between the outside rainfall display and also the indoor air obstacle a pressure-equalization chamber is developed in the glazing pocket, which serves to lower water infiltration by eliminating (matching) the stress distinction throughout the rainfall screen that has a tendency to require water right into the system.Water-managed systems show up comparable initially look, including drains pipes and also cries from the glazing pocket, but no effort is made to create an air obstacle or "zone-glaze" each glass or spandrel device, and as a result a bigger amount of water is pushed into the system as well as should be weeped away. Likewise, considering that no air obstacle exists, the stress differential between the glazing pocket and the interior may be strong enough to compel water up and down greater than indoor gaskets, leading to leaks.

Weeping of water is only an additional function. Note that the easiest means to identify a pressure-equalized rainfall display system is yo note that the that polishing pocket around each individual unit of glass is isolated air tight from nearby systems, the majority of obviously with plugs or seals at the gaps between screw splines at mullion crossways.

Some aluminum curtain wall systems are still created as face-sealed obstacle wall surfaces. They rely on continuous and also ideal seals in between the glass systems and also the structure and also between all frame members to do. The lasting dependability of such seals is incredibly suspicious and such systems need to be avoided. General curtain wall surface thermal efficiency is a feature of the glazing infill panel, the structure, building and construction behind opaque (spandrel and column cover) locations, as well as the boundary details.

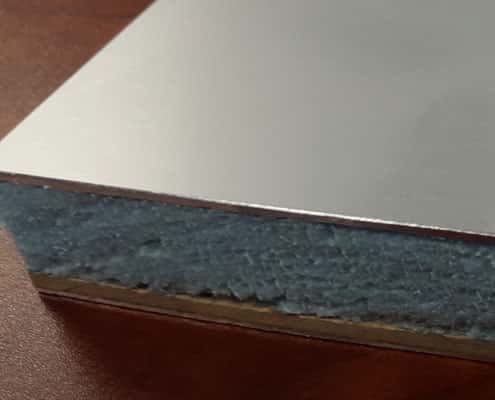

thermal break) (glass infill panels). Light weight aluminum has an extremely high thermal conductivity. It is common technique to integrate thermal breaks of low conductivity products, generally PVC, Neoprene rubber, polyurethane as well as extra lately polyester-reinforced nylon, for enhanced thermal efficiency. Some "put and debridged" polyurethane thermal breaks reduce and emphasize types in the thermal break when the exterior light weight aluminum moves in different ways from the indoor aluminum because of temperature distinctions.

skip debridging or "t-in-a box"). A real thermal break is" thick minimum as well as can be up to 1" or extra, with the polyester strengthened nylon variety. Some drape wall systems integrate separators that are less than ", making them "thermally enhanced". The deeper thermal breaks can enhance thermal performance and also condensation resistance of the system.

The Ultimate Guide To In Fill Panels

These systems regularly consist of gaskets that are put between the stress bar as well as mullions and feature as thermal breaks as well as help with acoustic seclusion. These systems need unique treatment in design and also building and construction to make sure continuity of the gaskets at straight as well as upright shifts. Gaskets are also made use of to support the glass on the interior and also exterior faces of the glass.

There is generally a void in the gasket at the edges after contraction takes place. With an effectively created system the water that goes into the system spandrel panel buy at the gasket corners will weep out through the snap cover weep openings. To minimize contraction of gaskets back from the edges making use of vulcanized edges and also diagonally cut splices are advised.

Because of the absence of indoor air beside opaque drape wall surface locations, these areas are subject to large swings in temperature as well as moisture as well as call for careful detailing of insulation as well as air/vapor obstacles to decrease condensation. Some drape wall systems include condensation drain arrangements, such as condensate seamless gutters, that are planned to collect and weep condensate from spandrel areas to the exterior; such condensate rain gutters and also weeps are a violation of the air barrier of the curtain panel filler wall unless they are outboard of the backpan.

At the drape wall surface border, keeping continuity of the air barrier reduces air flows around the drape wall surface. Assimilation of border flashings aids ensure watertight performance of the curtain wall and also its connection to adjacent wall aspects. Appropriate positioning of insulation at the drape wall surface border reduces energy loss and potential condensation issues.

The spandrel area is typically not heated up, hence the indoor atmosphere does not warm click site the mullions and counter the movement of the chilly temperatures deep into the wall surface. In the vision area the interior warmth aids to alleviate the chilly and protects against condensation. Consequently, do not shield between the interior section of mullions as well as adjacent wall surface building and construction either.

Water can go into the exterior wall surface system through five various pressures: gravity, kinetic energy, air stress difference, surface area tension, and capillary activity. To reduce water infiltration, all of these pressures need to be represented in the system layout. Unlike discontinuous windows, which are smaller sized units and also can depend to a high level on sill flashings to catch frame edge leakage, drape walls cover big areas of wall without sill flashings at each polished opening.

A Biased View of Infill Panel Wall Insulated

Water tight structure edge building and good glazing pocket water drainage are essential for trusted water infiltration resistance. Secret visual features of drape wall surfaces are glazing look (see Polishing) as well as sightlines. Sightlines are defined as the aesthetic account of the vertical and straight mullions. glass infill panels for stairs. The sightlines are a feature of both the width and deepness of the curtain wall surface framework.

Where narrow sightlines are preferred, steel stiffeners inserted right into the hollow framework of aluminum extrusions can help lower structure deepness. The acoustic efficiency of curtain walls is largely a function of the glazing and also inner seals to stop air leak (covered somewhere else). The sound depletion ability of drape wall surfaces can be improved by mounting sound undermining infill as well as by making construction as impermeable as possible.

This can be completed by raising the density of among the lites of glass or by integrating a laminated layer of glass with a noise-reducing interlayer, usually a polyvinyl butyral or PVB. Back pans are metal sheets, typically aluminum or galvanized steel, that are affixed and also secured to the curtain wall framing around the border behind nontransparent locations of a curtain wall - infill panels for windows.